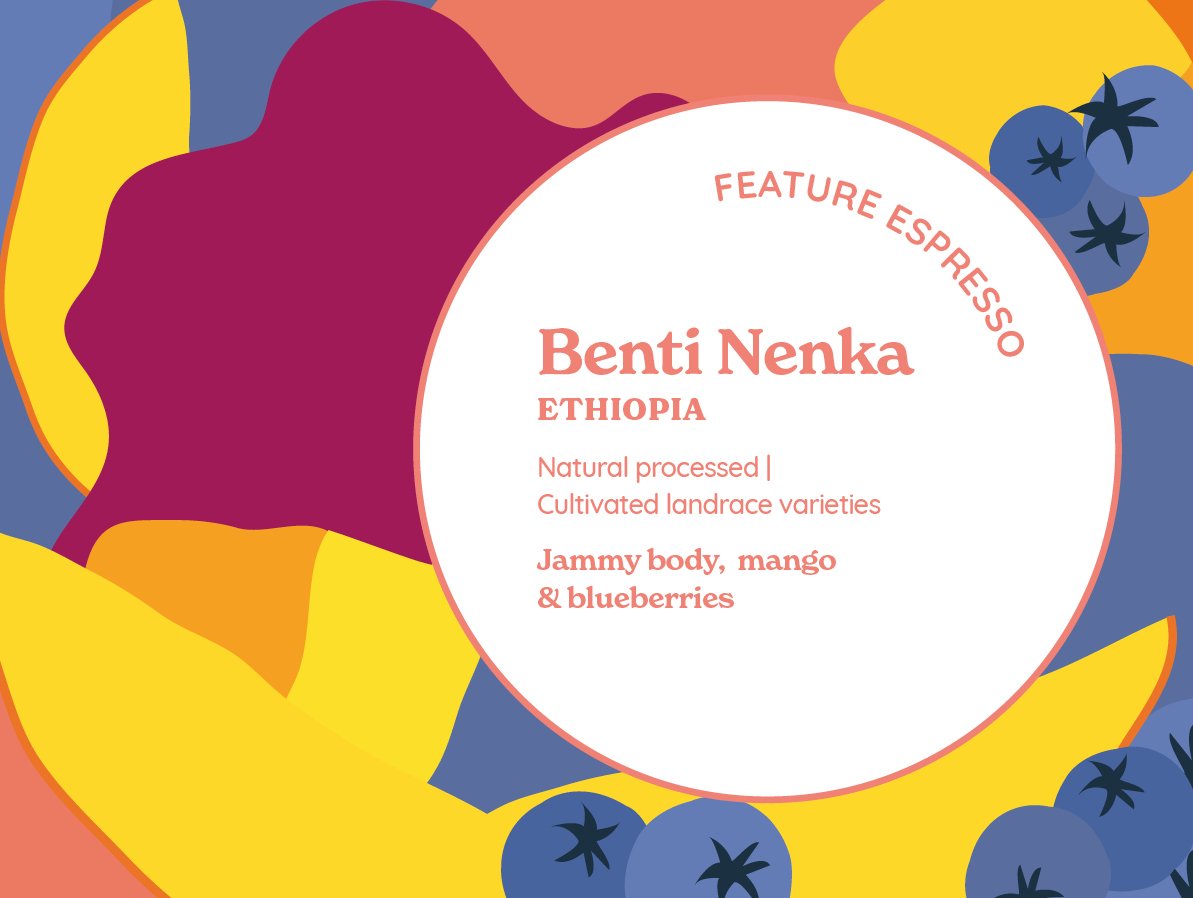

FEATURE ESPRESSO | Benti Nenka (Natural) | Ethiopia

FEATURE ESPRESSO | Benti Nenka (Natural) | Ethiopia

For best results we would always recommend purchasing whole bean and grinding fresh before brewing. If you don't have a grinder, we can grind according to your preferred brewing method just before shipping.

This coffee is great for espresso machines and stovetops as well as a fuller bodied aeropress or cafetière brews. Great on its own and with milk.

SHIPPING & DISPATCH:

Our e-commerce orders are shipped Mon - Fri. Same day dispatch cut off is 12pm. Orders places after 12pm on Friday are dispatched on Monday.

Key origin info:

Producer: Smallholder growers, based around the Benti Nenka village

Processed at: Guduba station

Region: Hambela Wamena woreda, Guji Zone, Oromia

Altitude: 1900 - 2170 masl

Variety: Local cultivated landrace varieties

Process: Natural, sun-dried on raised beds

Exporter: Exchange Trading PLC | Importer: Falcon Specialty

Cup profile: Jammy body, mango & blueberry

Purchasing history: 1st purchase 2024

More about Benti Nenka as shared by our import partner Falcon:

Located in the Benti Nenka village of Hambela Wamena, Guji, the Guduba Wet Mill processes coffee from 589 smallholder farmers, each managing plots ranging from 1 to 2 hectares. Established in 2012, the mill sits at an elevation of 1,900 to 2,170 meters, contributing to the coffee's unique quality.

Guji farmers adhere to traditional farming practices, often intercropping coffee with other food crops to maximize land use. These farms operate organically by default, with minimal reliance on fertilizers or pesticides. Most agricultural tasks, including harvesting, are performed manually due to the small scale of the farms.

The coffee cherry is hand-picked by the farmers and transported to the mill’s collection points, where it undergoes meticulous sorting and selection to remove any overripe, under-ripe, or damaged beans, ensuring excellent quality selection for further processing of speciality grade export coffees. While Benti Nenka has a cold anaerobic processing facility, this lot went straight to raised African beds where it undergoes a slow-drying process, taking 20 to 25 days in partial shade on elevated African beds until reaching a moisture content of 11%. Regular turning of the coffee ensures proper air circulation and temperature control to prevent over-fermentation and mould.

A moisture meter is used to monitor and regulate the moisture level. Once it reaches 11%, the coffee is then transported to a local warehouse, where further sorting and quality control measures are upheld to prepare the coffee for the final milling and export stage.